Welcome to the official website YUSH Electronic Technology Co.,Ltd

Find quality Depaneling Manufacturers_v-cut Machine Suppliers _PCB cutting machine Exporters_PCB Router Importers_pcb cutting machine Wholesalers

| SE series reflow oven main specifications | ||||||||||

| Model No | YSL-708AHSE | YSL-708HSE | YSL-708NHSE | YSL-710AHSE | YSL-710HSE | YSL-710NHSE | YSL-712AHSE | YSL-712HSE | YSL-712NHSE | YSL-706AHSE |

| Heating System | ||||||||||

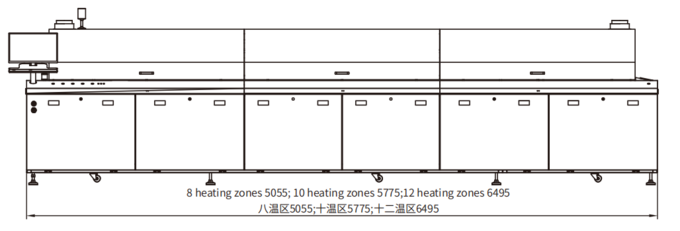

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | 6 heating zones, 12 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | 2230mm | ||||||

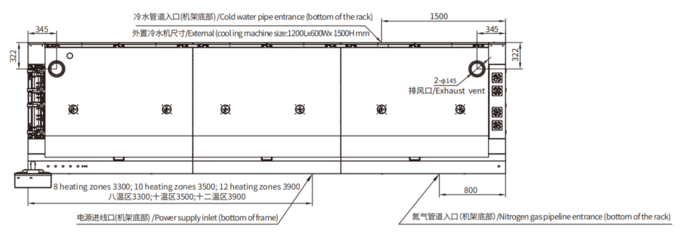

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | Double cooling:forced air cooling | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | |||||||||

| Conveyor System | ||||||||||

| Product width | Min50mm-Max400mm | |||||||||

| Conveying Direction | L→R,R→L | |||||||||

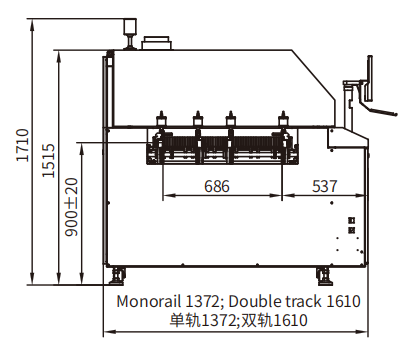

| Inlet Height | 900±20mm | |||||||||

| Fixed Rail Side | Front rail Fixed (Option:Rear Rail Fixed) | |||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | |||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | |||||||||

| Conveying speed | 300mm-1500mm/min | |||||||||

| Control System | ||||||||||

| Power Supply | AC3 5W 380V 50/60Hz | |||||||||

| Total Power | 57KW | 71KW | 89KW | 45KW | ||||||

| Start Up Power | 30KW | 35KW | 40KW | 30KW | ||||||

| Running Power | 7.5KW | 9.5KW | 11.5KW | 6KW | ||||||

| Temperature Range | Room temperature to 320℃ | |||||||||

| Control type | PC+PLC Control system | |||||||||

| Rail Width Adjusting Mode | Electric+Manual | |||||||||

| Temp Control accuracy | ±1℃ | |||||||||

| PCB Temp Deviation | ±1℃ | |||||||||

| Data Storage | Process Data and status stotage | |||||||||

| Power Outage Protection | Equipped UPS | |||||||||

| Operation interface | Windows Chinese simplified,English online free switching | |||||||||

| General | ||||||||||

| Dimension(L*W*H) | 5055*1372*1515mm | 5775*1372*1515mm | 6495*1372*1515mm | 4335*1372*1515mm | ||||||

| Weight | 2000-2200KG | 2400-2600KG | 2800-3000KG | 1600-1800KG | ||||||

| Color | Bright wrinkled white | |||||||||