Welcome to the official website YUSH Electronic Technology Co.,Ltd

Find quality Depaneling Manufacturers_v-cut Machine Suppliers _PCB cutting machine Exporters_PCB Router Importers_pcb cutting machine Wholesalers

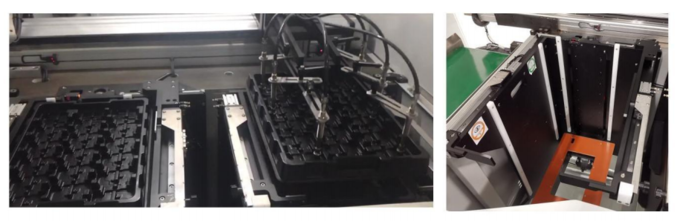

Tray automatic change module Tray lifting platform

Applicable product specification

| Device name | Tray Plate Receiver |

| Suitable for maximum size of subboard | 350*300mm |

| Suitable for Tray size | 180*250mm(min) ~ 450*350mm(max) |

| Tray stack height | 400mm |

| Tray is carried | Manual labor |

| Take-up direction | Left-right/right-left |

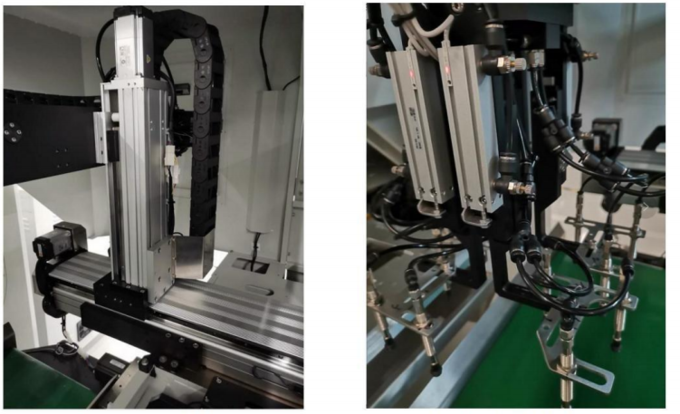

| Feeding and discharging method | Vacuum sucker adsorption transfer load |

| Number of feeding sucker modules | 4 groups (independent control) |

| Feeding and discharging control mode | X/Y/Z/R axis servo motor control |

| Tray lifting and shifting mode | Stepper motor (brake) |

| Load moving speed (maximum) | 800mm/min |

| Load shifting repetition accuracy | The 0.05 mm |

| Take-and-drop efficiency | 12-15 seconds /4 small pcs |

| PCB mobile function | Translation, rotation 90 degrees, rotation 180 degrees |

| Control system | Microcomputer (PLC) /PC |

| Operating interface | Touch Chinese interface |

| Power supply specification | AC220V 50/60 Hz single phase |

| Compressed air | 0.6MPA (with filter included) |

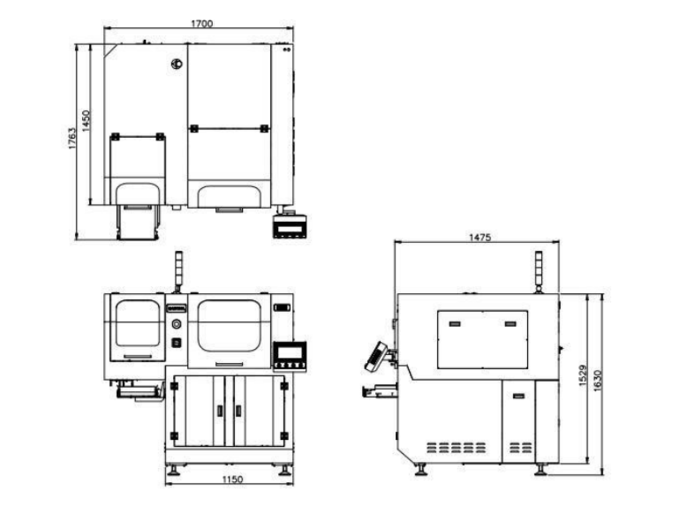

| Overall dimension | About 1500(W)*1475(D)*1800(H)mm |

| weight | 450Kg |

| power | 3.2 KW |